Hotspot Legend

-

Power & Performance

-

Operator Assistance

-

Cost of Ownership

-

Ergonomics & Controls

** The product shown may be different than the actual configuration based on market requirements and/or customer specifications.

*** Some products may be shown with optional equipment. Actual equipment features may vary.

The parking brake engages automatically once the trucks comes to a stop after the accelerator pedal is released. This feature prevents roll back on ramps.

The parking brake disengages when the accelerator pedal is activated. If on a ramp, the parking only disengages when enough torque is available to start moving the truck which prevents the risk of roll back.

Removes the need for traditional pedals, levers, or buttons to activate parking brake.

Sensors constantly monitor the steering angle and speed of the truck.

Sensors constantly monitor the steering angle and speed of the truck. When tolerances are exceeded, the truck's control system automatically responds to reduce speed early in the maneuver.

This feature helps to reinforce safe driving habits. This can also increase operator confidence levels and productivity, as top turning speeds are automatically restricted.

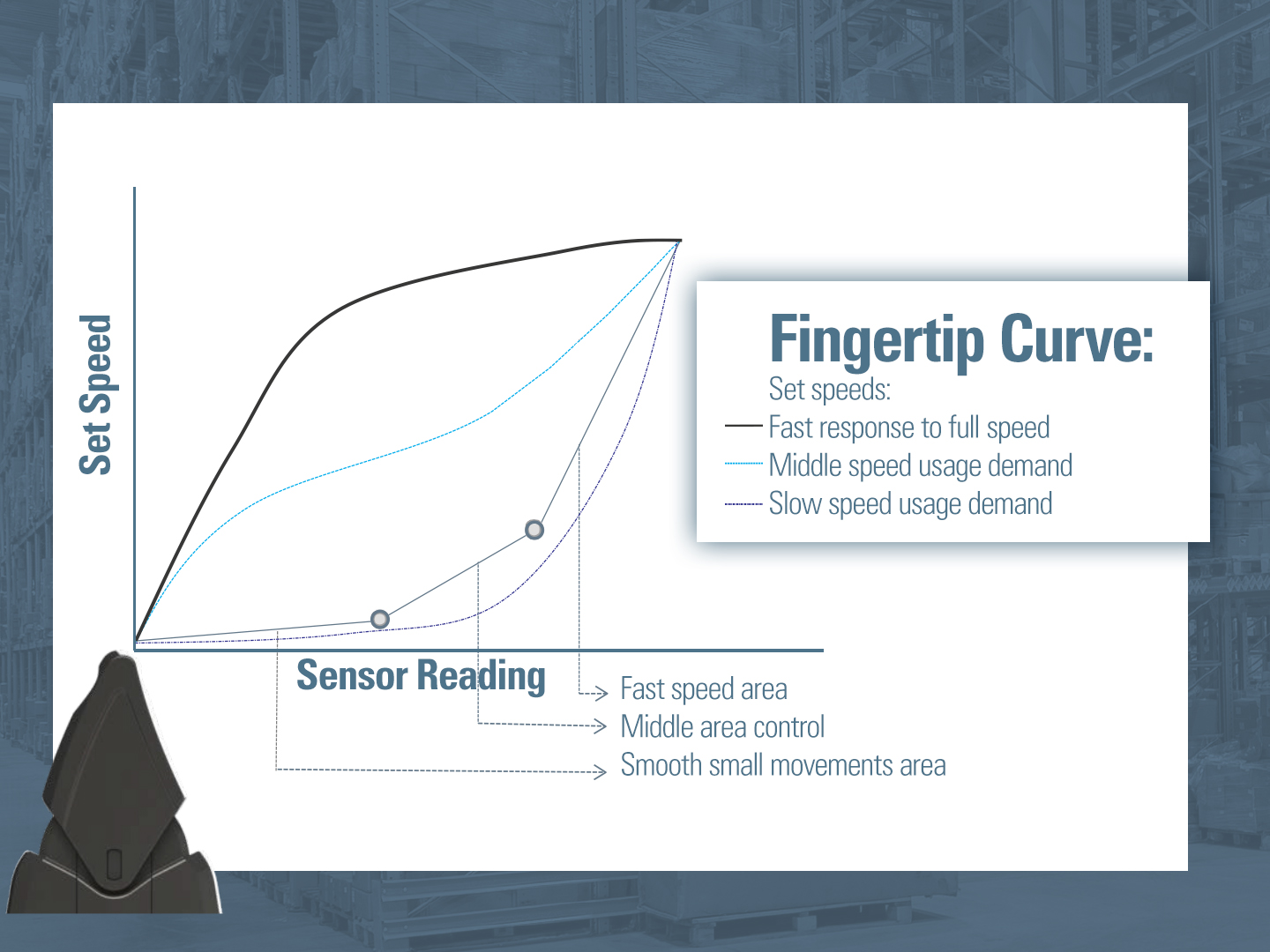

Adaptive speed control adjusts truck performance modes in reaction to quickness of foot and fingertip movements. This allows the truck to meet a driver's changing needs and ensures smooth starts and stops.

This feature is a computer-based feedback system that is activated if the operator unfastens the seat belt during operation,

is not in the normal operating position or exits the truck without the parking brake being activated

When standard procedure is not followed, the system will:

- Electronically stop powered travel of the truck and stop activation of load handling functions (hydraulics).

- Initiate a seat belt warning indicator (both buzzer and icon)

- Initiate parking brake reminder (both buzzer and icon)

Electronic control feature that helps to lessen mast and carriage sway with any load lifted over 11.5 ft (3.5m).

When the control system engages this feature, the wheel brakes are opened temporarily, transferring mast sway energy to the chassis and dampening the sway at the load.

Allows operators to confidently handle raised loads moving in or out of racking.

*Available on the MXST14 - MXS20, MX2-25 - MX2-35L, and MXL40 - MXL55

Long-lasting battery enhances performance by minimizing the need

for frequent charging or changes.

Quick-connect access permits fast charging when necessary. Fast battery compartment

access speeds up servicing and exchanges.

There are several options for battery handling:

1. Overhead Lift Out Battery Extraction (Standard)

2. Sideways Exchange Integrated Roller Bed (Option)

- Roller height from the floor is approximately 6.3" (160 mm) depending on tire wear

- Includes "swing open" side door

3. Sideways Exchange Battery Trays (Option)

- Two separate parts for smaller and larger battery box options

- To be used with sideways battery extraction chassis

- Tray slides in and out of truck's battery compartment using included tray rollers

The MXS series uses regenerative braking in normal driving and

brake pedal usage. Brake lights are controlled by the regen system.

The brake lights start to blink when regen is active and the truck is slowing down.

When the brake pedal is pressed, brake lights will be on constantly.

*Requires rear combination lights (option) for operation.

- Indicates work zone to pedestrians

- Increases awareness of truck operation in low light conditions

- Can be mounted on the side of OHG, if needed

The blue spotlights are designed to notify pedestrians of the

truck's presence by projecting a blue spotlight on the ground.

Depending on the direction of travel, the lights will project in front of or behind

the truck, warning pedestrians of its proximity.

LED working lights come standard with MXS models

- 2 forward facing mast-mounted worklights

- 1 rearward facing OHG-mounted worklight